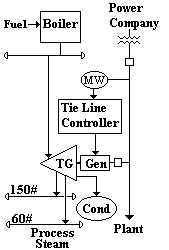

OptiMaxx - Tie Line Controller Overview

OptiMaxx is a suite of software modules specifically designed to minimize your total cost of

electricity. Software programs are embedded directly into your facilities existing control

system or may reside in a stand-alone computer connected via an OPC or Modbus interface.

OptiMaxx continuously calculates your facilities marginal cost to generate electricity

internally, based on fuel costs, boiler efficiencies, turbine efficiencies, condensing and

venting costs. Other variables, specific to your site, may be included, as required.

Your facilities internal marginal cost to generate power is continuously compared with the

current market price, which is retrieved over the Internet. Based on price differences,

OptiMaxx decides to either buy or make power. Depending on your specific electrical

contract, a decision to sell or shed electrical power may be included, if applicable.

Based on calculated decisions, OptiMaxx software automatically drives condensing steam

turbine generators to an optimum operating point while observing myriads of process

constraints. Typical constraints include: emission limits, boiler limits, turbine and generator

limits, contractual limits and more.

electricity. Software programs are embedded directly into your facilities existing control

system or may reside in a stand-alone computer connected via an OPC or Modbus interface.

OptiMaxx continuously calculates your facilities marginal cost to generate electricity

internally, based on fuel costs, boiler efficiencies, turbine efficiencies, condensing and

venting costs. Other variables, specific to your site, may be included, as required.

Your facilities internal marginal cost to generate power is continuously compared with the

current market price, which is retrieved over the Internet. Based on price differences,

OptiMaxx decides to either buy or make power. Depending on your specific electrical

contract, a decision to sell or shed electrical power may be included, if applicable.

Based on calculated decisions, OptiMaxx software automatically drives condensing steam

turbine generators to an optimum operating point while observing myriads of process

constraints. Typical constraints include: emission limits, boiler limits, turbine and generator

limits, contractual limits and more.

If economical, OptiMaxx may even choose to vent steam to make additional power with

non-condensing steam turbine generators. If available, gas turbines may also be included in the

overall optimization of electrical generation.

Unlike other systems that take several minutes to calculate the next move, OptiMaxx software is

quick. Every second, OptiMaxx continuously captures opportunities to minimize overall energy costs

by moving your process to the lowest cost solution. The result is incredible savings! Due to high

fossil fuel prices, installation of OptiMaxx usually pays for itself in only a few months.

non-condensing steam turbine generators. If available, gas turbines may also be included in the

overall optimization of electrical generation.

Unlike other systems that take several minutes to calculate the next move, OptiMaxx software is

quick. Every second, OptiMaxx continuously captures opportunities to minimize overall energy costs

by moving your process to the lowest cost solution. The result is incredible savings! Due to high

fossil fuel prices, installation of OptiMaxx usually pays for itself in only a few months.

A unique feature of OptiMaxx is a text messaging system that informs Operators and Managers what is preventing the control

software from doing better. Typical messages are, "Can't increase boiler load because ID fan is at maximum." or "Can't buy

more power because turbine condensing load is minimized."

software from doing better. Typical messages are, "Can't increase boiler load because ID fan is at maximum." or "Can't buy

more power because turbine condensing load is minimized."

Frequency distributions of system constraints are tabulated each day for performance analysis and reports. These reports

easily identify and prioritize equipment improvements needed to increase savings even more. Using OptiMaxx reports,

improvement projects are quickly justified because returns on investment are easy to evaluate and assign.

In addition to Real-Time Pricing control, OptiMaxx supports traditional interval demand tie-line control and instantaneous MW

purchase control. Depending on your facilities requirements, these additional controls may be included:

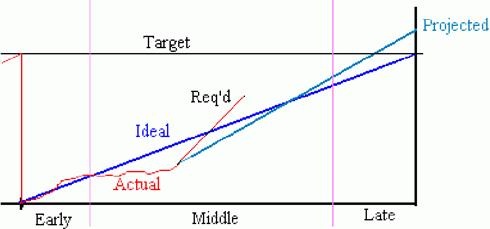

Interval Demand Megawatt Hour Purchase Control - In this mode, electrical power is purchased during your Power

Company's demand interval. A pulse is received from the Power Company each interval to synchronize clocks. OptiMaxx

control software monitors the Power Company's purchase meters and adjusts power generation, based on minutes left in the

interval, the amount of electricity already purchased, the instantaneous MW purchase and the MW Target. OptiMaxx controller

uses three different control strategies, depending on minutes left in the interval. OptiMaxx optimizes buying electricity to

exactly reach the MW target at the end of the interval. But, it also prevents process bumps across interval boundaries by

matching instantaneous purchase megawatts to the target value.

easily identify and prioritize equipment improvements needed to increase savings even more. Using OptiMaxx reports,

improvement projects are quickly justified because returns on investment are easy to evaluate and assign.

In addition to Real-Time Pricing control, OptiMaxx supports traditional interval demand tie-line control and instantaneous MW

purchase control. Depending on your facilities requirements, these additional controls may be included:

Interval Demand Megawatt Hour Purchase Control - In this mode, electrical power is purchased during your Power

Company's demand interval. A pulse is received from the Power Company each interval to synchronize clocks. OptiMaxx

control software monitors the Power Company's purchase meters and adjusts power generation, based on minutes left in the

interval, the amount of electricity already purchased, the instantaneous MW purchase and the MW Target. OptiMaxx controller

uses three different control strategies, depending on minutes left in the interval. OptiMaxx optimizes buying electricity to

exactly reach the MW target at the end of the interval. But, it also prevents process bumps across interval boundaries by

matching instantaneous purchase megawatts to the target value.

Purchase Megawatt Control - In this

mode, an instantaneous purchase MW

target is maintained without regard to the

Power Company's interval demand

boundaries. This mode is typically used

during maintenance outages.

mode, an instantaneous purchase MW

target is maintained without regard to the

Power Company's interval demand

boundaries. This mode is typically used

during maintenance outages.

Load Shedding - Some facilities choose

to implement our electrical load-shedding

module to prevent setting new interval

demand peaks or purchasing very

expensive power. Smart Decision making

software ensures only a maximum

number of prioritized loads are shed to

prevent penalties or minimize overall

to implement our electrical load-shedding

module to prevent setting new interval

demand peaks or purchasing very

expensive power. Smart Decision making

software ensures only a maximum

number of prioritized loads are shed to

prevent penalties or minimize overall

electrical cost. Usually, load priorities are preset in tables but

Conclusion - Responding correctly to real-time pricing signals can reduce overall electrical costs, significantly. Many

companies across North America are enjoying incredible energy savings with OptiMaxx process control software. Soon, you will

too!

companies across North America are enjoying incredible energy savings with OptiMaxx process control software. Soon, you will

too!

| Copyright © 2023 Dynamic Energy Systems |